What is deburring?

Deburring is an essential process in industry and especially in the aeronautic sector, which consists of removing the burrs and projections generated on a part when it is cut.

Why choose an Extrom deburring machine ?

To ensure your safety

Deburring using our industrial machines allows you to obtain parts with smooth edges, rounded contours, no roughness, with even internal and external edges, avoiding any risks of cuts!

For easy assembly, mounting and application of coating

Without deburring, small discrepancies could appear between your different parts, meaning that your assemblies do not quite comply with the plans. When you choose an Extrom deburring machine, you choose precision to the nearest hundredth of a millimetre !

To improve productivity

All our deburring machines are designed to operate quickly and accurately, in a fully automated manner, which is a real time-saver for your employees and, as a result, your company!

Laser and plasma cut parts

DM 1100 Z2C EVO

• Deburring and Double side Edge Rounding up to 1100mm

• Ideal for burrs removal and double side edge rounding up to 1100mm working width.

DM 1100 ZC EVO

• Single-Sided

• Deburring & Edge Rounding

• Top Line Automated

• 1100mm Width

DM 1600 Z

• Single-Sided

• Deburring or Surface Finishing

• Job-Shop Version

• 1600mm Width

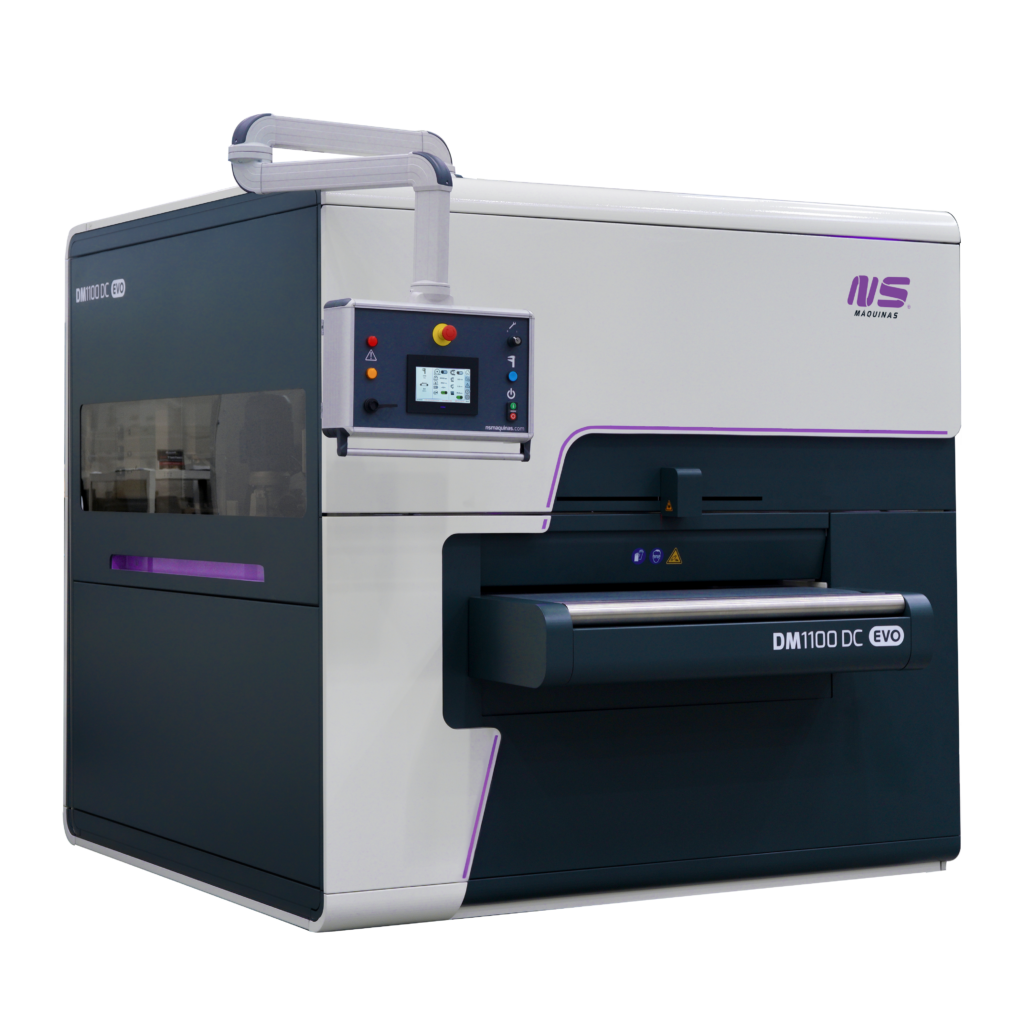

DM1100 DC EVO

• Single-Sided

• Slag Removal & Edge Rounding

• Heavy-Duty Automated

• 1100mm Width

Tubes and deburring tumbler

Are you in need of specific advice?

Make an appointment with one of our representatives in your region!